A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

A better environment begins with steel

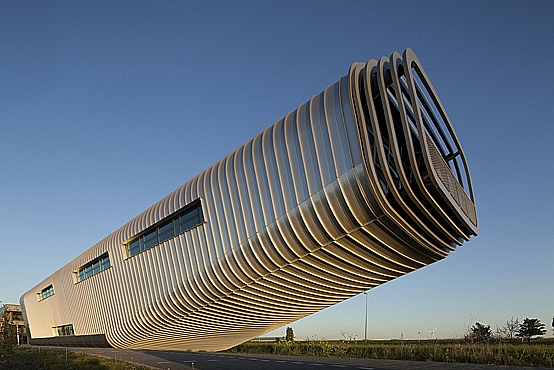

Wilo Nederland industrial building, Westzaan (Benthem Crouwel Architects).

This energy efficient building was inspired by the core business of Wilo Netherlands; the manufacture of water pumps. Benthem Crouwel Architects gave the 1,330 m2 GFA two-storey building a remarkable tubular cantilever structure rising from a small wedge-shaped location to a height of about 20 m above the water. The cantilever is supported by two fully visible trusses, consisting of HEA and HEB profiles. The heaviest profile is an HEB 550 underneath the overhang.

To keep the profiles in the overhang as light as possible, a light roof structure using E=MC2 steel roof profiles from SAB was chosen. The channels in the steel sheets were filled with a mixture of Micronal paraffin beads in a concrete matrix. Pipes embedded in the mix provide cooling or if necessary low temperature heating. Sealed insulating material was applied above the concrete in the channels.

The PCM in the steel roof is mainly to prevent the interior spaces heating up too rapidly or becoming overheated. The PCM does not just operate passively to cushion temperature fluctuations. It can also be activated by the coupling with the heating and cold storage system.

The PCM is only 4% of the mass of the roof construction, however, this 4% results in a doubling of the thermal mass. The concrete operates as a containment system for the PCM. Thanks to the PCM, the lightweight Wilo building has been economically made thermally heavy.

_____

Location: Rak, Hoogtij Industrial Estate, Westzaan • Assignment: Wilo Netherland • Architecture: Benthem Crouwel Architects • Structural engineering consultants: Pieters Bouwtechniek, Delft • Building physics consultants: Deerns Consulting Engineers • Main contractor: De Geus Bouw • Steel fabrication: Oostingh Staalbouw • Roofing and cladding systems: SAB-Profiel • PCM: BASF • Photos: Benthem Crouwel Architects.

_____

Floating Pavilion, Rotterdam (Public Domain Architects and Deltasync)

The City of Rotterdam has future plans for sustainable floating districts in the City Port area. The potential of this innovation has been demonstrated by the floating pavilion in Rijnhaven. The pavilion houses an information and exhibition centre which features living on the water. The complex consists of three interconnected half spheres, each 12 m high and 18.5, 20 and 24 m in diameter respectively. The trio has a combined floor area of 46 x 24 m.

The three domes share one buoyancy chamber; the second buoyancy chamber serves as a meeting plaza. The floating bodies are made up of five layers of expanded polystyrene (EPS) from 20 to 75 cm thick. In the thickest layer there is a grid of concrete beams with a concrete floor on top and concrete slabs on all sides, which serve as a hard shell to protect the island from the influence of wave action for example.

The buoyancy chamber has a minimal thickness of 2.25 m, thanks to the lightweight structure of the domes: steel structures coated with ETFE foil. The ETFE foil is a highly transparent plastic from Vector Foiltec that is approximately 100 times lighter than glass.

To a large extent the pavilion can meet its own energy needs. Division into different "climate zones" enables the energy to be used where needed at any time. The energy for heating and cooling comes from solar collectors and the surface water.

In the auditorium - the smallest dome - PCMs have been used, due to the rapidly changing heat load caused by changing occupancies. The function of the PCMs is to cushion the temperature fluctuations in the rooms.

Demand for cooling during the day is met by recirculation of air round the PCM and by indirect evaporative cooling in combination with sorption and solar collectors. In the evening an air conditioning unit ensures that the PCM is "reloaded".

_____

Location: Rijnhaven (next to Heyplaat RDM campus), Rotterdam • Assignment: City of Rotterdam (Rotterdam Climate Initiative) • Design: Public Domain Architects and DeltaSync • Building physics: DWA • Installation technology: Unica • Construction: Dura Vermeer Bouw Rotterdam • PCM: Autarkis

_____